Significantly increased lead times, learning to work as a remote team, and learning to work without certain tools or resources: these were just some of the challenges 2020 handed us. Adaptive businesses overcame many hurdles around working in a remote environment. Resilient workforces evolved to work with changing tools and are doing quite well with those challenges. The one remaining hurdle 2020 gifted us, is a significant increase in lead time for many products.

5 Tasks to Do Now for Better Lead Time Management

Is your company still dealing with the challenge of expediting products needed for a customer ASAP? If so, take a look at these 5 tasks. Your company should already be addressing these options to address difficult lead times for parts.

-

Update resource planning tools with actual lead times. Ensure you are ordering with adequate time for delivery

- Long lead times can be planned for and addressed properly, the variability in lead time is the real problem that hurts production planning. If your resource planning system is programmed to order a servo drive 2 weeks before the instrument or machine is due, but the real-world lead time for that servo drive is 10 weeks – you are set up to fail before the order is even placed. Failing to have the correct lead time in your system also results in efficiency loss. Your team will spend extra time expediting with your supplier wasting time for both companies. Also, your customer service team will spend extra time working with your customer, responding to their order status update requests. Update your resource planning system with the current lead time for your purchased products to ensure the system operates effectively.

-

Update resource planning tools with adjustments to safety stock levels. Keep production flowing

- Once you know how long it takes to get the part, adjust safety stock levels. This ensures you cover any production gaps or product shortages. Simply knowing it takes six weeks to get a linear motor instead of two weeks, implies you need to move your linear motor safety stock to cover at least 6 weeks of consumption instead of 2.

-

Revise forecasting models ensuring the changes in sales are accounted for in the model

- The more your lead time impacts your customer demand, the more flexible your forecast needs to be. If you lose 50% of your imaging instrument business due to a 10% increase in the lead time of an XY precision linear stage inside the machine, make sure your forecast accounts for this. If this demand change isn’t taken into consideration, you will quickly build up inventory that will likely sit on your shelf until you have enough of the right inventory to reduce your lead time again. This ultimately creates a whipsaw process with oversupply periods and undersupply periods versus customer expectations over a given timeframe.

-

Explore new suppliers who stock items instead of companies running a just-in-time (JIT) process

- The above options are there to react to the increased lead time issues. Exploring new suppliers is a task that can help you find a solution to fix your lead time expansions. As noted by Brightwork Research – Internal projects to reduce lead time have been proposed for decades by Lean and Six Sigma evangelists as a type of fools gold. These types of resources typically subscribe to a philosophy that ignores constraints in the supply chain. The complexity of the parts that make up a machine derail the concept of getting everything there just in time. There is no substitute for having the products in stock, on the shelf, ready to ship. Find suppliers and companies who have in-stock motion components or are willing to stock for you. Qualifying a new supplier in your system can be challenging, but the reward may be well worth the effort.

-

Find alternative parts with better lead times where it makes sense (this can be challenging in certain regulated environments)

- If you need a 2-stack servo motor quickly but are getting quoted extended lead times, explore the option for a longer stack length servo motor. This task will require engineering and purchasing to work together to find an alternative product that will still meet the key application requirements. When executed properly, finding substitute products can result in significantly reduced lead time.

Ultimately the answer to reducing your lead time may not involve the same supplier or exact part number you bought at your last purchase cycle. Your traditional supplier may not have solved their material lead time issues either, which in turn will impact your order and your customer’s satisfaction. Find alternatives to the traditional route, if possible find companies that carry your product in inventory. For some “inventory” can be a bad word, but having the right in-stock motion components eliminates most of the challenges caused by lead time variations.

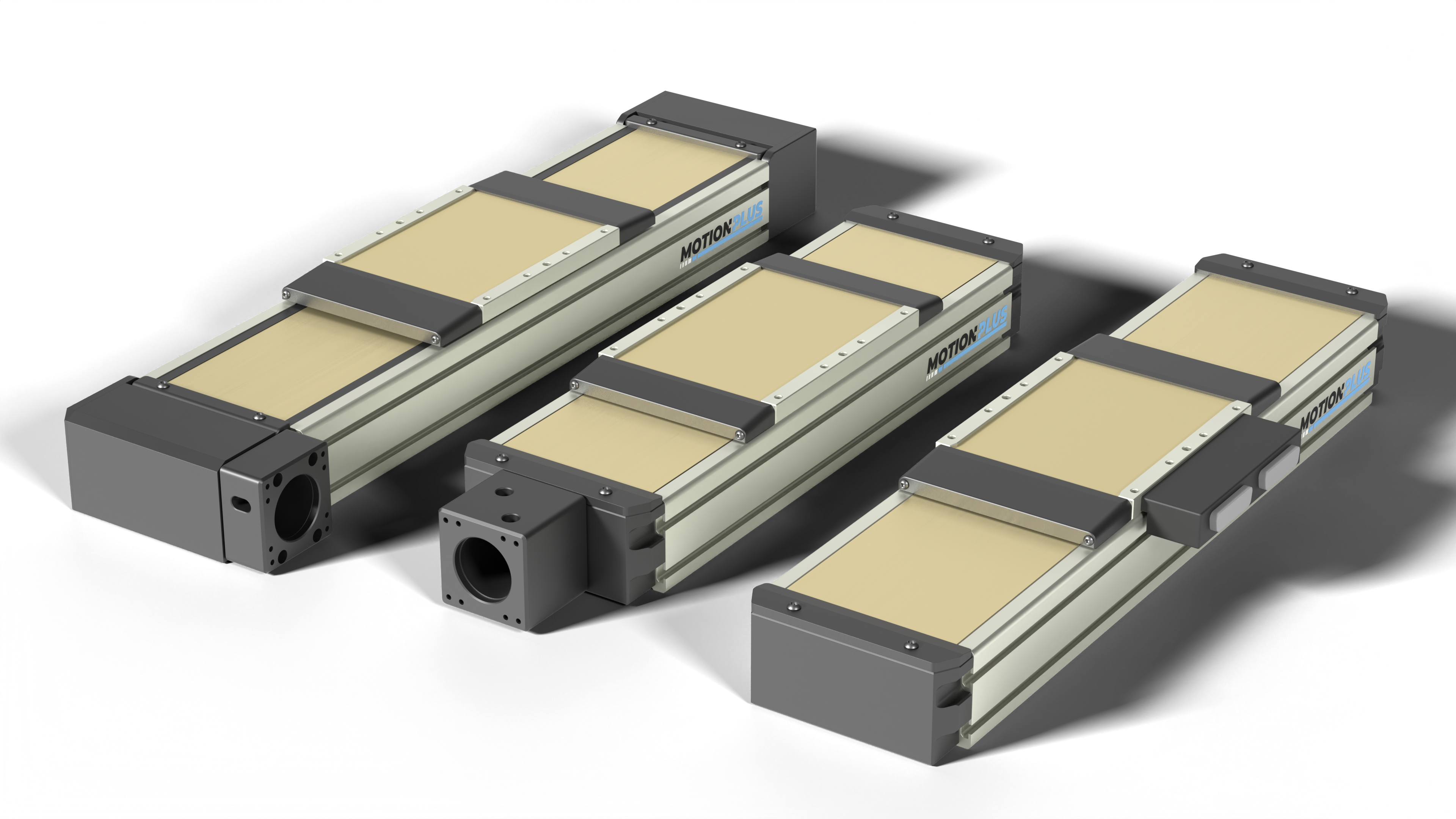

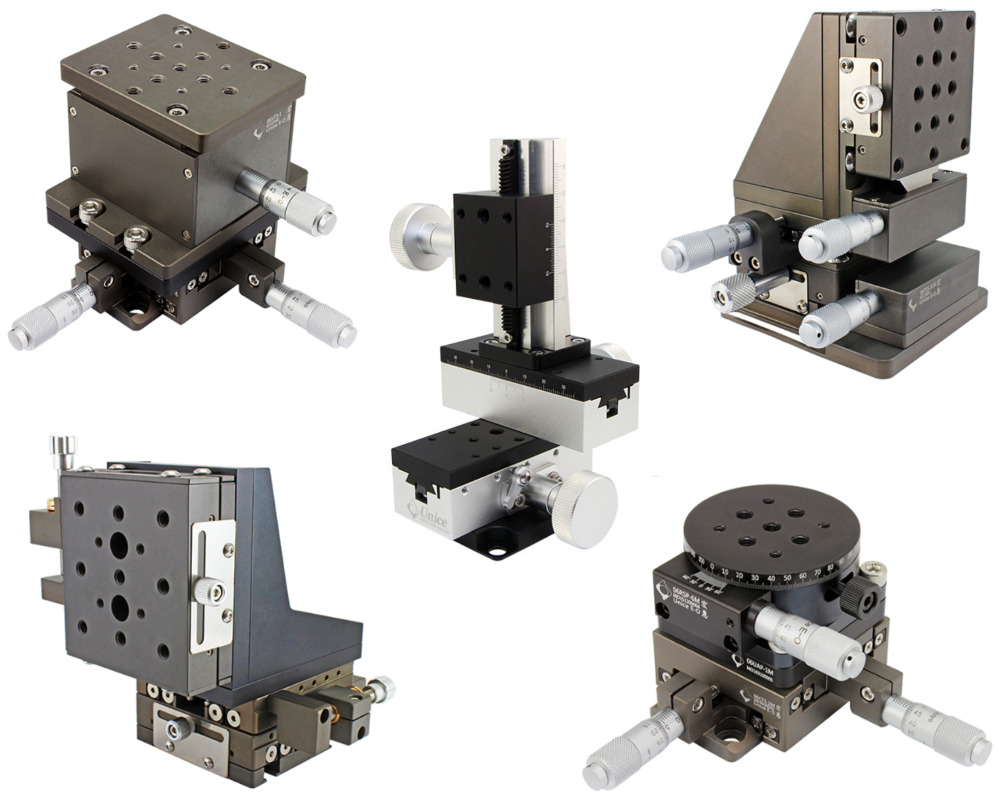

In-stock Motion Components from Motion Plus Including Actuators, Drives, Motors, and More

At Motion Plus we have a significant amount of inventory that many companies deem too difficult to stock. Our inventory contains:

- Precision linear actuators (Aerotech PRO stages, Micronix PPS stages, and more) fully built, configured and ready to ship

- Linear and Rotary motors (servo or stepper) ready to ship

- Precision miniature piezo stages on the shelf and ready to ship

- Motion Controllers and Servo, Stepper, Piezo Drives (PWM and Liner) packaged and ready to ship

If you would like to know more about what is in stock, click here and log in (or create) to your account to see product availability and in-stock options.