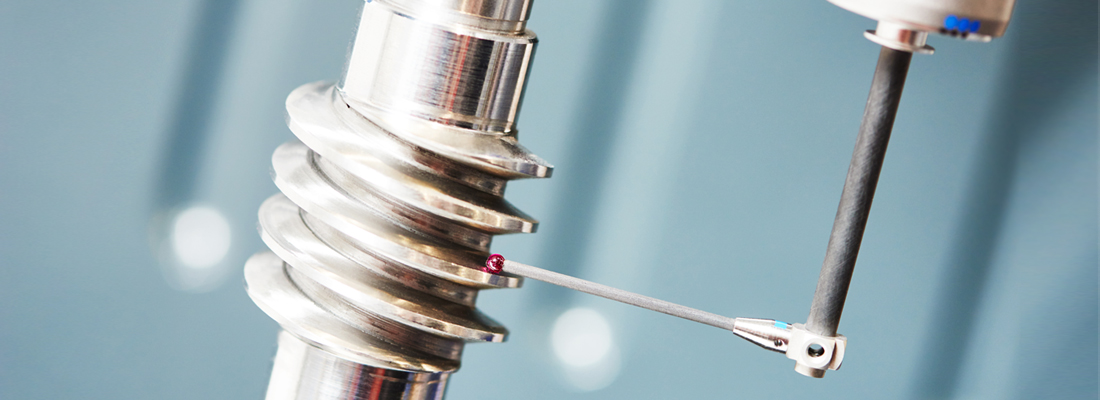

Precision positioning, coordinated motion for high-speed imaging and inspection.

INSPECTION AND METROLOGY POSITIONING SOLUTIONS ENABLE HIGH SPEED IMAGE CAPTURE AND MAXIMIZE THROUGHPUT

Reduce your node sizes and increase your throughput by utilizing our motion control technology. Our solutions will enable tighter tolerances, higher resolutions, and more repeatable results. Our portfolio includes precision XY integrated solutions which shrink your overall machine design, integrated rotary axis and focal adjust stages for an easy to integrate solution from one partner.

HOW CAN WE HELP WITH YOUR METROLOGY & INSPECTION NEEDS?

With Precision Controls:

- Full coordinated motion capability to ensure multi-axis coordination across stepper, servo and piezo solutions

- Position Synchronized Output (PSO) allows for triggering a process event on a calibrated encoder position.

- Infinite Field of View (for Galvo Applications) allows the AGV series to process large areas in seconds, limited only by the maximum speeds of the servo-stages

- CADFusion CAD to G-Code Software allows for easy importing of vector-based drawing files and produces motion programs for our Aerotech controllers

- Friction Compensation: Advanced algorithms to remove errors attributed to friction, allowing you to quickly step and settle to the smallest of distances

With Motors & Precision Positioning Stages:

- Linear motors with the highest copper density for maximum force output

- High resolution and fidelity force and velocity control

- Accuracy Calibration

- Easily build calibration files for single axis or multi-axis configurations based on known errors in the system

- Utilize feedback devices that communicate directly with our position-based laser triggering hardware

- Multi-axis assemblies from 2 to 6+ degrees of freedom are tailored for complex contours

SUCCESSES

APPLICATION AREAS

MOTION CONTROL & AUTOMATION FOR:

- Thin Film Measurement

- Optical Wafer Inspection (Defect Inspection, Metrology, Defect Review, Critical Dimension)

- Electron/Ion Beam Inspection

- Microscopy (Scanning Electron Microscopy (SEM), Atomic Force Microscopy (AFM))

- Reticle/Mask Inspection

KEY PRODUCTS

KEY APPLICATION NEEDS

- Low precision foup transport automation

- High precision positioning

- High speed motion

- Smooth velocity stability with no jitter